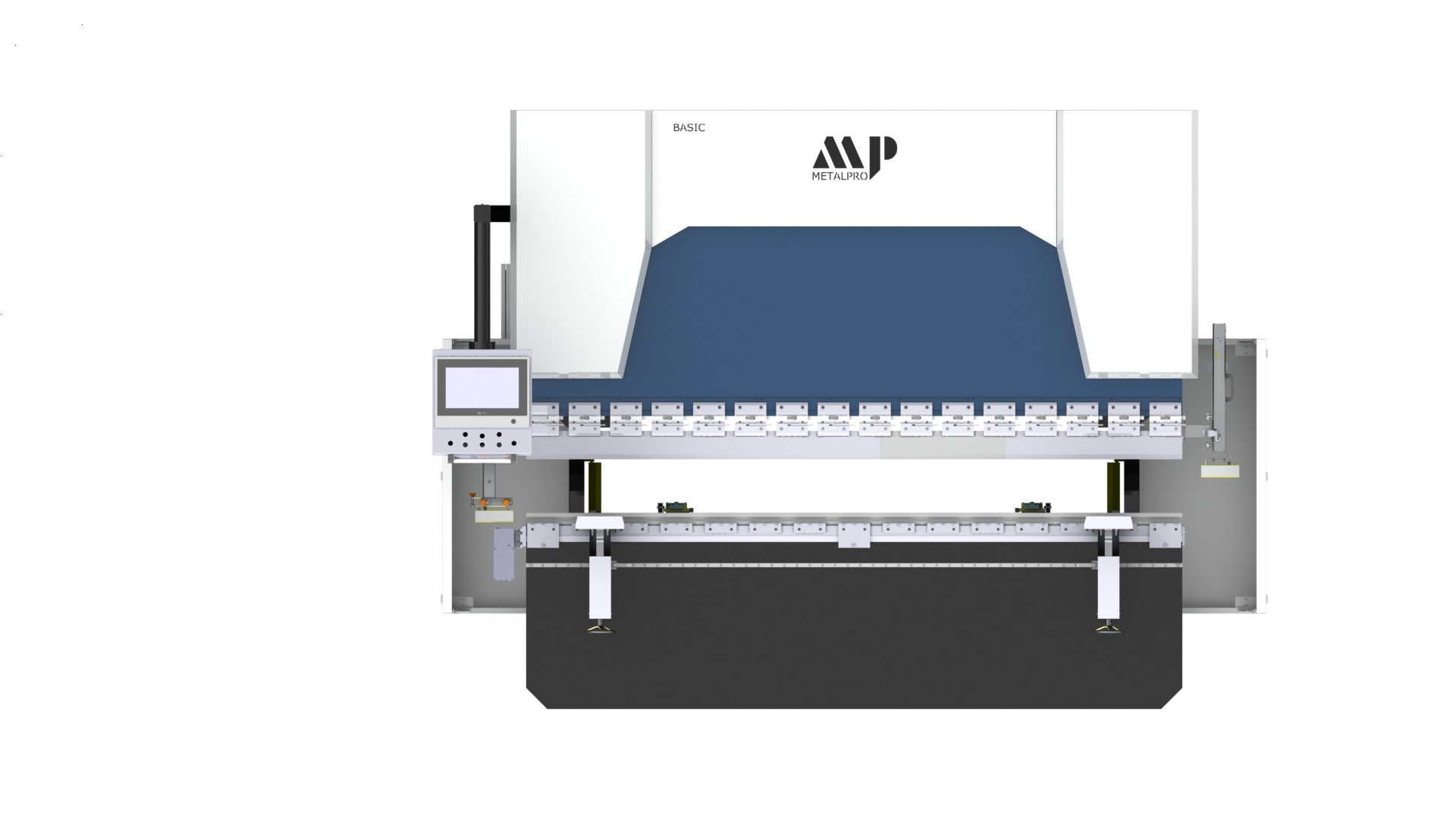

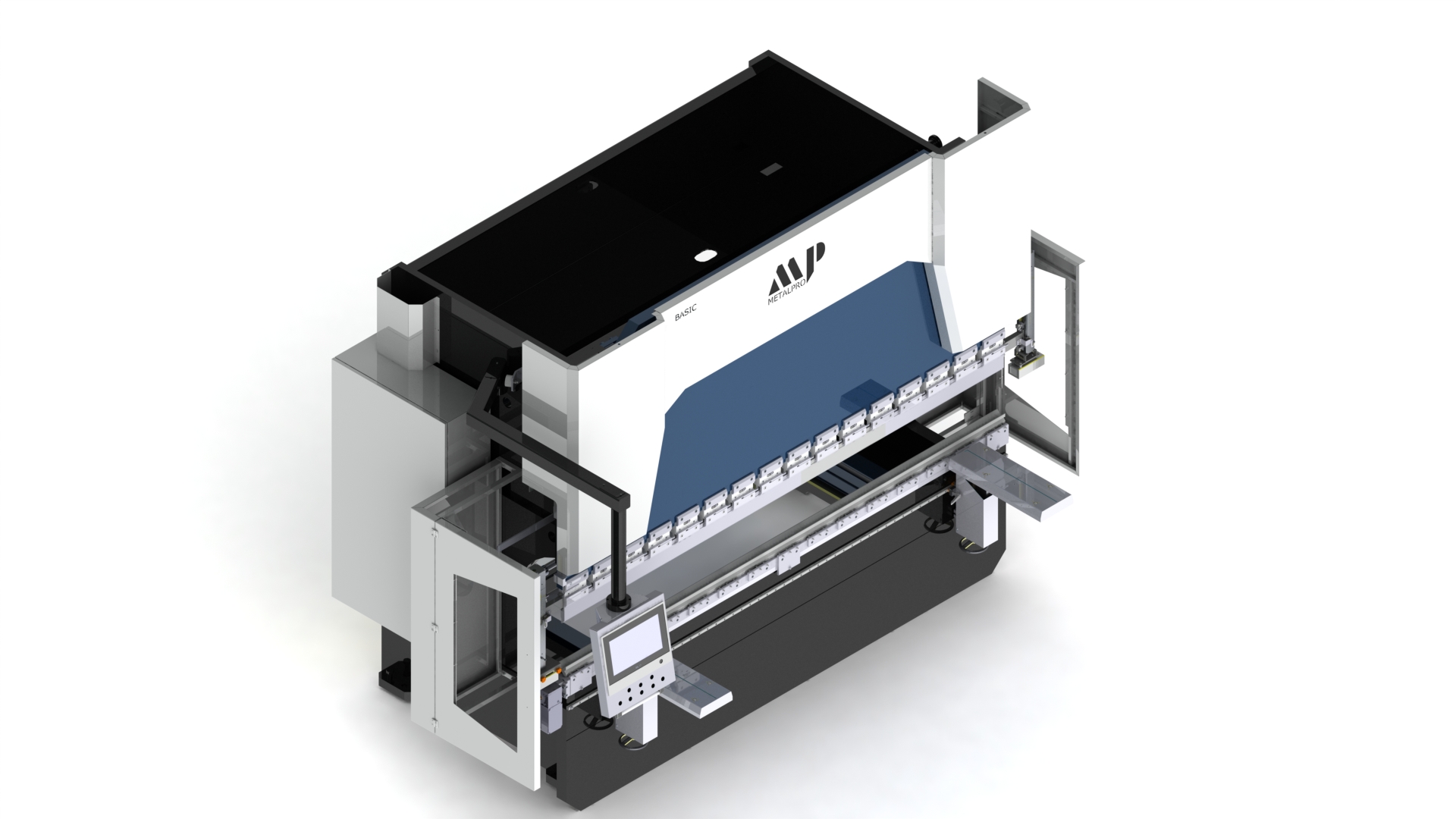

Basic is designed and built for customers who process simple parts and do not need to run their press brake for more than a couple of hours a day. Easy to use control and simple operation of Basic makes it convenient for customers who require a budget solution for their simple bending requirements.

Basic is an entry level press brake but by sharing the same modular structure with Advance, it makes no compromise on quality, consistency and dependability.

Customers that choose Basic will enjoy a large throat depth, high stroke and daylight for deep box bendings, dependable hydraulic system and high precision linear scale system.

Standard Equipments

- Rigid frame designed on SolidWorks with stress and deflection analysis, welded by certified welders and machined to 0,01 mm precision in single piece.

- Step Automation RK 12 - 10″ touchscreen control with graphic visualization.

- Dependable servo hydraulic system provided by Hoerbieger.

- Honed, chrome covered cylinders with high precision ground pistons

- Y1-Y2 synchronized hydraulic cylinders running on dual ram guides on each side for smooth ascend and descend.

- Single axis backgauge (X) with manual height adjustment, running on ballscrews for maximum accuracy .

- European and/or American style punch clamps

- European die holder with quick change mechanism.

- Full length precision ground and hardened punch and 4V die set.

- High stroke and daylight for deep box/panel bending.

- 500 mm throat depth to utilize full length and deep bends.

- High resolution linear scales with an accuracy of 0,01 mm for precise bending.

- Front support arms sliding on linear guides to easily gauge small parts.

Optional Equipments

- Front laser guards for finger protection.

- Manual crowning of die bed for even angles along full length of bend.

- Automatic crowning of die bed for even angles along full length of bend.

- Custom design throat, stroke and daylight.

- Large selection of punches and dies.