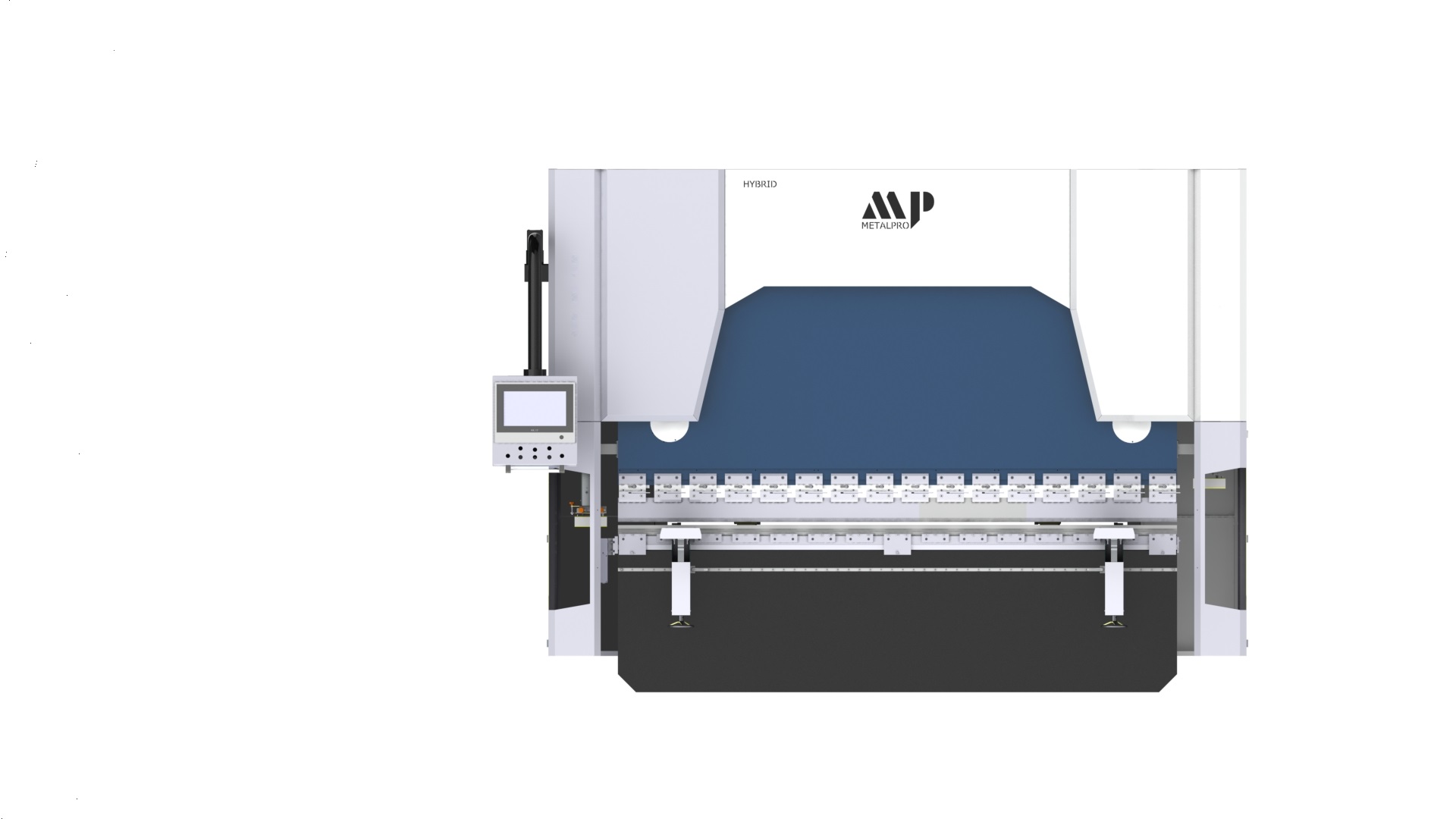

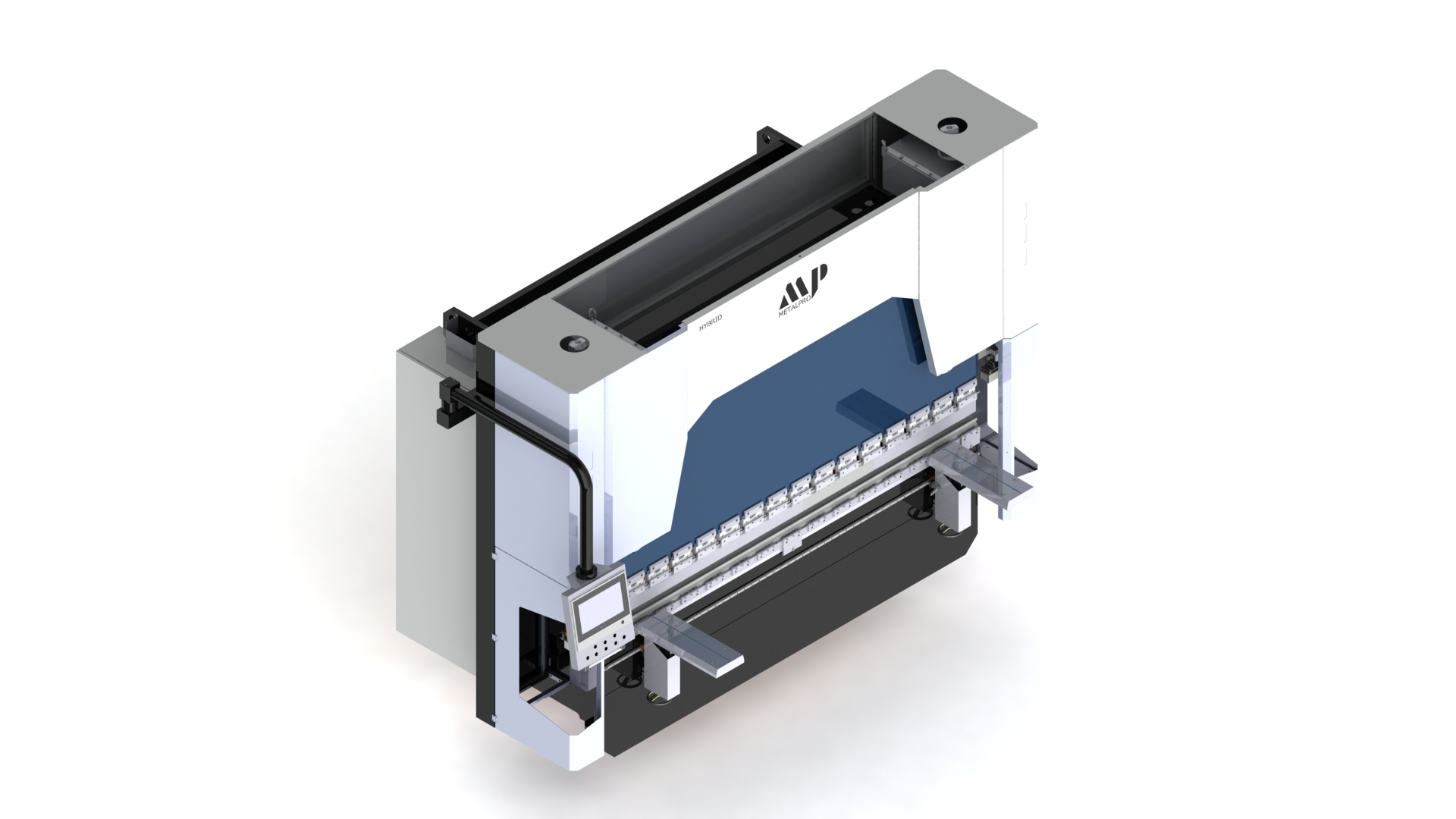

Hybrid press brake is our innovative solution for this decade's most pressing issue…soaring energy costs. Every manufacturer is observing the effects of energy prices that is on a continuous rise and to be more efficient in a production environment is not only beneficial but crucial to survive. For this reason, we have developed Hybrid, a hybrid press brake that uses a servo motor and servo pump with variable oil flow control instead of the traditional AC motors and fixed flow pumps. With this advanced hydraulic system, our customers will have three key benefits compared to hydraulic press brakes;- Hybrid consumes up to %70 less energy compared to traditional hydraulic press brakes.- Hybrid requires up to %50 less hydraulic oil to run compared to traditional hydraulic press brakes. Lifetime of the hydraulic oil is also much longer (up to two times) since oil only circulates in the system during actual bending as opposed to continuous oil circulation on traditional hydraulic press brakes even when it is idle. Also no oil coolant is required for Hybrid even in the most demanding production environments.- Silent operation of the machine (up to 15 dB lower sound levels) compared to traditional hydraulic press brakes.

Standard Features

* Rigid frame designed on SolidWorks with stress and defeection analysis, welded by certified welders and machined to 0,01 mm precision in single piece.

* Step Automation RK 15 (15" 2D) graphic touchscreen control.

* Dependable servo hydraulic system with servo motors and servo pumps provided by HAWE.

* Honed, chrome covered cylinders with high precision ground pistons

* Y1-Y2 synchronized hydraulic cylinders running on dual ram guides on each side for smooth ascend and descend

* 2 axis aluminium extrusion backgauge (X,R) running on ballscrews and double linear guides with servo motors to easily gauge parts

* European and/or American style punch clamps

* European die holder with quick change mechanism

* Manual crowning of die bed for even angles along full length of bend

* High stroke (280 mm) and daylight (520 mm) for deep box/panel bending

* 500 mm throat depth to utilize full length and deep bends.

* High resolution linear scales with an accuracy of 0,01 mm for precise bending.

* Front support arms sliding on linear guides to easily gauge small parts.

Optional Features

* Next 3.0 3D CNC Controller- Front laser guards for finger protection.

* Automatic crowning of die bed for even angles along full length of bend

* Custom design throat, stroke and daylight.

* Large selection of punches and dies.

* Tandem Preparation

* Automatic Lubrication System